As labor shortages continue to run rampant through the manufacturing industry, manufacturers are increasingly looking towards artificial intelligence to continue to meet demand. Crucially, manufacturing companies in 2024 are looking towards AI not just as a tool to streamline processes, but as a spark for innovation that could redefine the operations of a supply chain.

“You know, a lot of folks initially used AI for just analysis, supply chain optimization, or enterprise resource planning,” said Edward Mehr, chief executive of Chatsworth-based technology manufacturer Machina Labs.

Mehr’s firm is one of many Los Angeles-based companies in manufacturing that is looking toward a new way to wield AI – Mehr refers to it as ‘the third generation.’

“They’re actually taking over the process,” Mehr said of Machina Labs’ technology. “They’re actually informing how to do a process that maybe previously was either not possible, or you had to create very fixed custom tooling for it to enable that which made it very inflexible, meaning that you had to build certain type of tooling and equipment for every part that you’re trying to manufacture.”

Per GrayMatter Robotics, U.S. manufacturing is a $2.5 trillion industry with 3.8 million unfilled jobs. Solutions are needed for processes that often require highly skilled labor in conditions not without hazards, and the flexibility, adaptability and speed offered by AI are being applied as short-term solutions as much as they are being looked at as ways to overcome manufacturing hurdles that were unavoidable in a pre-AI world.

“The benefit of the flexibility (provided by AI) is that you get your parts faster,” Mehr explained. “You don’t have to tool up a factory before you can get your batch of parts. So it reduces lead time. But more importantly, it allows you to create factories that last longer.”

Adaptability has not been a strong suit of factories, especially those in technology, aerospace, or other types of metalwork, which Mehr attributed to the customized nature of manufacturing in those industries. Oftentimes, a factory is created with the specific part needing to be manufactured in mind, and all aspects of the factory from architecture to operations are designed with that one specific part in mind. However, if a part were to be changed, upgraded, or otherwise rendered obsolete in its current form, the factory specifically designed to carry out that task would be rendered obsolete as well, along with its resources.

Artificial intelligence offers the potential of a new level of factory adaptability, and what is being tried by many companies in Southern California could lead to a new standard of efficiency in manufacturing that has the potential to permanently redefine the industry nationwide.

Mehr and Machina Labs’ AI-powered robots are just one of many new ideas being tested in the manufacturing space.

Being in L.A. “gives you an advantage as an advanced manufacturing company using new technology,” explained Mehr. “Being in this ecosystem where Boeing and Lockheed and Northrop Grumman and SpaceX are your neighbors make it much easier to deploy new technologies versus other regions.”

• • •

Advanced Bionics is the only manufacturer of cochlear implants in the U.S., according to the company. AB was founded in Valencia and has brought its technology to 130 countries worldwide since its 1993 inception. It is part of the larger Sonova organization, which specializes in hearing care solutions and is comprised of Advanced Bionics, Phonak, Unitron, Hansaton, AudioNova and Sennheiser.

It is through its partnership with Phonak that Advanced Bionics uses artificial intelligence.

Advanced Bionics’ latest cochlear implant Marvel CI operates on a universal Bluetooth connection and is equipped with Phonak’s AI-powered AutoSense OS 3.0, which reduces background noise and improves hearing focus.

“Since its introduction in 2020, Marvel CI has redefined hearing performance with cochlear implants,” Victoria E.Carr-Brendel, then-president of Advanced Bionics, said in a statement in December. “Marvel CI’s universal Bluetooth connectivity, dedicated sound processor for children, and integrated compatibility with Phonak hearing devices are still features that are unique and unmatched on the market.”

Advanced Bionics Chief Executive Alistar Simpson assumed his new position, as well as the group vice president for Cochlear Implants on the Sonova Management Board, after Carr-Brendel stepped down last month. Carr-Brendel had served in both positions for five years. With Simpson at the helm, AB is looking to leverage its breakthrough Marvel CI tech into further market expansion.

“AB has a strong foundation, and I look forward to working with the talented team to build on this success and drive further growth and innovation,” Simpson said at the time of his appointment as CEO.

• • •

Chatsworth-based Machina Labs specializes in developing new manufacturing technology. Founded in 2019, the company’s total funding crested the $45 million mark following a $32 million series B funding round last year. For Machina Labs, finding ways to utilize AI to streamline technological manufacturing is the name of the game.

“The core problem we’re solving is making factories that can easily change when the hardware or the product that you’re trying to manufacture is changing,” Machina Labs Chief Executive Edward Mehr said. “Most factories are custom built for the parts and the material and the design that they’re trying to manufacture. And the moment you want to change the design, or you want to change the material, you have to invest in a whole set of new tooling and new machinery that is specific for that product.”

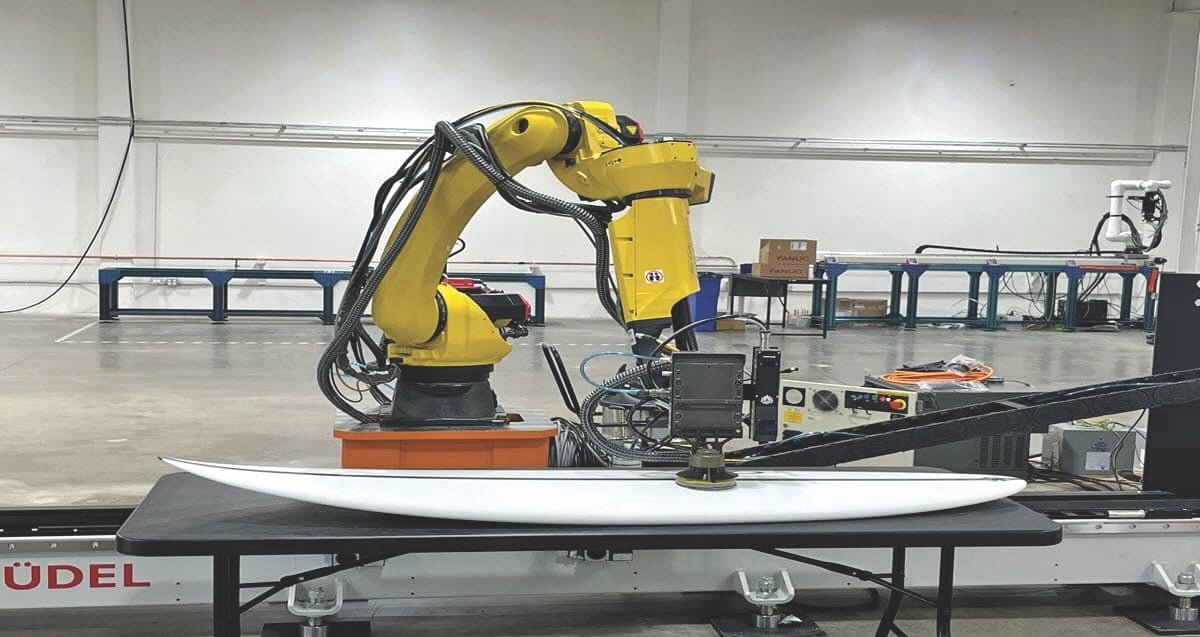

Machina Labs’ solution comes in the form of what Mehr refers to as third-generation AI – the utilization of AI to innovate in the manufacturing space instead of simply streamlining or optimizing previously utilized systems. Flexibility in the highly specialized craft of metalwork is paramount for a company that can go from making aerospace parts to automobile parts in the same day, and Machina Labs’ Robo Craftsman is the core technology used to address this facet of technological manufacturing.

“It’s a robotic system, that pretty much works like how a craftsman works, right? It can pick up different tools, apply differently to the material, and replicate different types of manufacturing processes,” Mehr explained.

In the long-term, Machina Labs aims to use AI to develop manufacturing systems that can perform multiple highly specialized crafts to maximize factory longevity.

• • •

True to its name, GrayMatter Robotics mobilizes AI-powered robotics to solve manufacturing challenges. The Gardena-based company has had an eventful 2024 thus far – it won the Automate Innovation Award for its SCAN&GRIND system in May, then raised $45 million one month later. The $45 million raised in its series B funding round accounts for over 60% of GrayMatter Robotics’ total funding since its founding four years ago.

GrayMatter Robotics offers a variety of robotic solutions – competent in blasting, coating, trimming, spraying and more – to address the labor shortages currently plaguing the manufacturing industry. The main focus of the company’s approach is automating manufacturing and industrial operations to assist understaffed workforces in a consistent, efficient manner. GrayMatter Robotics’ solutions aim not to replace workers but to streamline complex tasks on the manufacturing floor while minimizing variables.

“We founded GrayMatter to enhance productivity while prioritizing workforce well-being,” Ariyan Kabir, the company’s co-founder and chief executive, said in a statement. “With our physics-based AI-powered systems, we are fulfilling our mission while unlocking new levels of efficiency and productivity.”

• • •

The origins of Lisi date all the way back to Paris circa 1777, but Lisi Aerospace – initially dubbed Blanc Aero Industries – was founded in 1977 when the group started designing and manufacturing fasteners and assembly solutions for the aerospace industry.

Today, Lisi Aerospace operates under the Lisi banner out of Torrance. The company designs and produces a very wide range of assembly systems, hydraulic fittings and metal structural components for the aerospace sector.

In May, Lisi announced the launch of a new AI initiative with Watch-Out, a high-precision machining partner of the group for nearly two decades.

“The Watch-Out solution, a technological feat of Machining 4.0, combines all the conventional machining cycles in a perpetual loop with a specific Artificial Intelligence. It is a virtually self-sufficient production machine that constantly self-corrects according to data generated and captured in real time on parts and tools,” Emmanuel Nieldez, Lisi’s chief executive, said in a statement.

“Much more than just an improvement on the performance offered by previous-generation machine tools, the Watch-Out solution represents a dramatic change in an industrial paradigm aimed at eliminating the element of randomness in the treatment of chronic failures in the production chain,” he added.

Lisi also has branches in the automotive and medical industries, but its main source of business continues to be the aerospace industry. Its most recent initiative is yet another example of a high-level manufacturer with innovation at the forefront of its approach to utilizing artificial intelligence.

• • •

Metal Toad is a business services company and Amazon Web Services specialist that operates primarily as a consulting partner to small- and mid-size businesses, as well as larger-scale manufacturers. Metal Toad was founded by Chief Executive Joaquin Lippincott in Portland, Oregon, in 2003. Lippincott relocated to Southern California in 2017 and opened its headquarters in Century City. Its Portland office is still open alongside an office in São Paulo that opened in 2020.

The majority of Metal Toad’s partners are small and midsize businesses, but the company has also worked with major manufacturers including Sony and Daimler.

Metal Toad’s also offers a myriad of services; the most recent addition to what the company offers is Securitoad.

Launched in June 2024, Securitoad is a security solution with IP blockers powered by AI algorithms.

“By combining an always-on, always-learning AI algorithm with simplified controls, security is handled in real-time, faster and at a scale that is simply beyond human capabilities,” Lippincott told AWS.

With Securitoad, Metal Toad has harnessed the power of AI to establish a simple, low-maintenance function to offer yet another level of cybersecurity to its partners. Lippincott’s hope is that Securitoad will allow technologists to put more focus on building for the future instead of daily maintenance.

“For Securitoad, we are targeting IT teams who would rather do something other than battling hackers day-in and day-out. We believe technologists want to do more than fight to keep their applications safe,” said Lippincott. “They should be empowered to innovate and design new solutions, not constantly fight fires. This might include overworked and understaffed teams, or teams led by visionary technology leaders looking to do more than fight their way to a stalemate.”