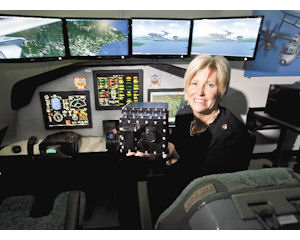

When the Messenger spacecraft entered orbit around Mercury in March 2011 all of its systems were shut down except one – the black box of a space inertial reference unit made in Woodland Hills by the Navigation Systems division of Northrop Grumman Corp. Tracking the progress of Messenger that day was Liz Iversen, general manager and sector vice president at Navigation Systems. The experience was one of those moments when Iversen said she can watch the technology developed by the division at work. “It was pretty cool,” Iversen said. Iversen developed early ties to the aerospace industry; her father worked as an engineer at Hughes Aircraft. She led Navigation Systems in celebrating its 50th anniversary last year of making gyroscopes and other navigation components for aircraft, ships, and spacecraft, and helicopter cockpits. Iversen’s responsibilities extend beyond the San Fernando Valley to manufacturing and development facilities in Salt Lake City, Germany and Italy. Travel is a prominent part of her job and life; she considers Philadelphia, where husband Ronald lives, her home base. Prior to her appointment in March 2010 to head up Navigation Systems, Iversen worked for Northrop’s Electronic Systems sector in Baltimore. Among the favorite aspects of her job: communicating the importance of the division’s work to employees. Navigation Systems makes components that allow pilots and other military personnel to not only reach their destination but to make it home, Iversen said. “When you say that to people it makes a big difference,” Iversen said. Question: Navigation Systems just celebrated 50 years. What do you see happening in the next 50 years? Answer: Continued innovation. We are already working on smaller, lighter, faster, more accurate IMUs (inertial measurement units). We are looking at how we integrate our sensors into the broader Northrop Grumman capability. Precision timing is huge. If you can align the space, the air, the land, the sea and the undersea and know exactly where you are at any time it sounds easy but it is not. We are the largest exporter in Northrop Grumman. We do a lot of work outside the United States. That will continue. On the other piece of our business, our glass cockpit business, we will have a long stretch in the retrofit capability. That is everything from a National Guard helicopter to ones we have deployed to air and ground to search and rescue. There are a lot of helicopters out there. Q: Where does Navigation Systems fit in the overall Northrop Grumman corporate structure? A: Northrop Grumman has four sectors. We are one of the four business units within the Electronic Systems sector. We are the smallest of the four businesses in overall sales and awards. We are number two in profitability. We have 3,000 people in navigation systems, which from a headcount perspective put us at number two in size, as well. At Navigation Systems we are on all of the platforms and that is across Northrop Grumman. We are on submarines, aircraft carriers, in the air, in space. Q: What is the role of the Woodland Hills facility to the division? A: This is the headquarters for the Navigation Systems business. We have roughly 1,200 people here. This is our design house of all of our navigation and for all of our situational awareness. We do all of the manufacturing for the space capability here and all of our advanced technology development here for our domestic business. This is where the heritage is. Tenure in this facility is above 25 years on average. Q: Can California do more to be competitive in the aerospace industry? Is the state losing business? A: The aerospace and defense business is based on the economy right now. I do not think we are losing anything being in California or anywhere else. I think it’s the state of the economy at the moment and where we are from a defense budget perspective. Our heritage is in California; that’s where we pull from a talent perspective. I don’t see us walking away from that. Q: Does the division develop products for specific customer needs or to get ahead of the curve? A: We are doing both. In the current marketplace, and from an economic perspective, we are focused on performance and cost for the current customer. From a research and development perspective, we are driving forward and working on more innovative approaches to deliver greater performance, or the same performance, at a lower cost. Q: Have you any sense of how proposed defense cuts will affect Navigation Systems? A: The good news about us is we are a tier three supplier and we are primarily commercial. We don’t see a significant impact. When it hits, it will be in 2014, but it is still less than 5 percent. For us, it is not a big impact. Q: The division did lay off employees last year. What was the reason for that? A: A lot of our development contracts that we had been developing for specific customers ran out. We just didn’t need as many engineers as we had in the past. Everyone is overemployed. We made sure that our folks would be too busy, rather than have extras around and have folks worry about their jobs. We are hiring very little amounts in specialties and specific areas and capabilities. We took about an 8 percent cut over all (in 2010 and 2011 in Woodland Hills and Salt Lake City) and we may have 10 to 15 jobs open. Q: Any loss of business because of budget cuts? A: We are holding our market share. We have been up the last couple of years about 10 percent. We are maintaining that. Customers are not paying for the customized systems at the moment. So the non-recurring (contracts) — we have not had a lot of those wins. To be honest, that is budgetary. The customers are saying, ‘Based on what you have right now, can I use what you have and continue on and make it through?’ Q: Five or six years ago, a big issue facing the aerospace industry was mass retirements in the Baby Boom generation. Did the recession change that? A: Absolutely it did. Our folks are holding out on retirement longer. That causes a compression problem. You want to bring in new folks at the same time but if folks aren’t retiring and they are doing great work you don’t want them to leave. About 45 percent of our population is retirement eligible today. Folks are hanging on. From a technical perspective we need them. Q: What are customers looking for from your components? A: Weight, cost, footprint and performance. Those are the things on the navigation side that they are looking to us to provide. We have been working hard on cost reduction efforts. We innovate and put in new technology that takes out weight or has a lower cost. I would qualify that, though. Customers are really looking for life cycle cost. One of the things we introduced was fiber optic gyros. Our mean time between failures on our previous gyros, our ring laser gyros, we would see them come in for repair maybe every three to five years. With fiber optic gyros it’s 10 years. Our repair business is not going up, but the customer is more satisfied because the time for repair and refurbishment is much longer. Q: What is the smallest component that you make? A: The G-2000 (gyroscope) is about the size of a quarter. In fact, it was the one used to find the Chilean miners (in the 2010 mining disaster). Title: Sector vice president and general manager, Northrop Grumman Navigation Systems Age: 51 EDUCATION: Bachelor’s degree in industrial engineering, business management and industrial psychology, Iowa State University Most Admired: Eleanor Roosevelt Career Turning Point: Vice President at General Electric at age 36 Personal: Married to Ronald J. Iversen; three children, Greg, Paige and Sarah Q: How much time do you spend at the other facilities? A: I spend a lot of time on the road. I am in Germany and Italy once every other month. I am in Salt Lake City once a month, if not twice a month. I am on the phone with them every other day at a minimum. I spend a lot of time with customers, as well. Q: What’s it like to be an executive in a male dominated industry? A: I went to college on a swimming scholarship the first year of Title IX and majored in engineering. I have competed against the male-dominated world for as long as I can remember. My father’s comment is, ‘No one is better than you are and you are as good as they are.’ It’s all about proving results. There are more women around than there used to be. That’s a lot of fun. I started the women’s leadership initiative within Electronic Systems sector and here, as well. If you help women, you help everyone. That’s really the focus — asking, how do we get more folks to step up and be leaders? Every once in a while I meet someone squirrely, but for the most part I haven’t had any issues. Northrop Grumman works hard to ensure there is a level playing field. Q: How did you get interested in aerospace? A: I grew up in it. I worked in aerospace for 10 years and then worked for General Electric and then for Johnson & Johnson and Gateway Computer. I went from this to the commercial side and had terrific experiences there. When you work for Northrop Grumman, you work with the spooky smart people because the technology is so far-reaching and leaning forward. Medical technology is terrific, and I worked in medical device and diagnostics businesses at Johnson & Johnson which was great. At GE, I worked in the financial businesses, so I learned how to do financial engineering. At Gateway, I ran quality and reliability worldwide and trained with the Japanese. There is nothing like the technology (at Northrop) and the people are wonderful. Q: How did the experience at non-aerospace companies help prepare you for working at Northrop? A: The financial capability I learned at General Electric and how to run a business. From a balance-sheet perspective, it’s more than just technical performance, it is how you drive overall financial returns and the appreciation of the market. When I went to Johnson & Johnson, it was all about brand. At Johnson & Johnson and Gateway, I had global jobs. I had folks all around the world. You learned how to work globally and act locally. How you select people, how you understand the cultures that are different, how you understand the rules and the law. In this job, because I have a German facility and an Italian facility, how we play in the United States is nothing like how you play outside the United States. How long it takes to sell a product, how you have to engage with the customer and what are they looking for. It is all about eye to eye and whether they trust you. Q: What is the coolest thing about your job? A: The people, and then the technology. The hardest thing about my job is you are always being watched. You need to be careful when you make a comment that folks don’t take it as direction. And getting my picture taken. I am not used to that. I like putting the people in front and not me.