At Lee’s Enterprise, an aircraft-parts manufacturer, the supply chain issues plaguing the industry are best exemplified by the small things that are not readily available.

Tom Molnar, the president of the Chatsworth-based company, said that a lot of the specialty hardware that used to be bought off the shelf is now coming up short.

“Things like bearings, even little dowel pins, in the past we could order, and it would be in stock somewhere and it was a question of how fast you wanted the shipping done,” Molnar said. “Now we are getting things like where it takes 10 weeks to get a glue. ‘Oh, you need a paint. We don’t have any paint. It’s going to take 14 weeks to get you paint.’ We are seeing a lot of little things like that.”

Lee’s Enterprise is not alone in facing what has become a global supply chain problem, which has popped up due to the Covid-19 pandemic forcing shutdowns in areas with high concentrations of manufacturers, particularly in China; increasing consumer demand; and backups at ports, especially in Southern California, home to two of the busiest ports in the world.

Additionally, there have been labor shortages in jobs key to keeping the supply chain operating smoothly.

As a result of those material and labor shortages, Molnar said previously easy-to-find items are now suddenly problematic.

“And it is not just one category. It is every single category of product that we buy from is having an issue,” Molnar continued. “So that causes a delay and suddenly we cannot ship that one part and then that screws up our customer.”

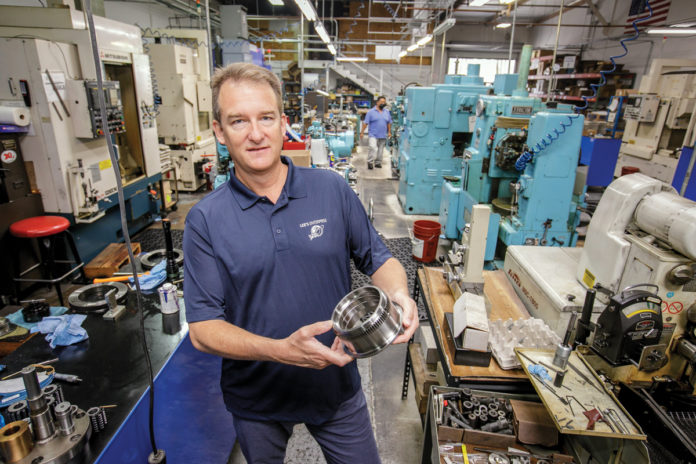

Lee’s Enterprise, founded in 1972, does aerospace work only. About 75% of its work is for military customers and 25% is for commercial aviation. The company makes parts and assemblies for a variety of aircrafts, machining parts from carbon steel, stainless steel, aluminum and other standard aircraft metals.

“We make parts that are specialty gears that go inside electromechanical actuators,” Molnar said. “So, our stuff has a lot of outside specialty processing done to it.”

After being machined at Lee’s facility, those parts are sent out for heat-treating and plating. But the firm is finding that the lead times at its heat treaters and platers are taking longer because they are short-staffed and experiencing a surge in work, Molnar said.

“They cannot hire enough employees to get the work out fast enough,” he added

David Fisher, owner of S&H Machine, a Burbank aircraft parts manufacturer, also sends his parts for commercial aircraft out to be heat-treated and plated.

He has hundreds of vendors working for the company and their cost of doing business has increased so they raised their prices, Fisher said, “which is putting a tremendous financial burden on shops like mine because we are locked into contracts and fixed pricing for many years, so that is making it challenging for companies like us.”

Due to supply chain and labor shortages, S&H is not taking on new work. Instead, it concentrates on the legacy work it has always done, Fisher said.

“I am turning away business I have not seen before because I don’t have the capacity to take it on right now, which is really sad,” he said.

To deal with the labor-shortage issue, Fisher hired a full-time recruiter – the first time he has ever had such a position at his company. In the past month, there have been four new employees hired, he said.

Automation is another way to deal with the labor shortage. While he does have some automated equipment, Fisher said he is looking to bring on more.

Since the start of the pandemic, there have been a lot of aerospace manufacturers who have not made it and had to close their businesses. This gives customers fewer options, he said.

“They have less suppliers to do their work and that is putting more load on the suppliers who are still in the business,” he added.

Limited quantities

David Goodreau, president of the Small Business Aerospace Industry Coalition, a Glendale-based national nonprofit network of independently owned small businesses manufacturing and supplying military aerospace spare parts, components and assemblies, said the coalition sold some manufacturing equipment, which included some simulators for CNC (computer numerical controlled) machines.

Another company purchased three of the simulators for a couple of thousand dollars and then did something interesting with them. Because computer chips are limited in quantity due to supply chain issues, the company took them out of the simulators and put them into other equipment, Goodreau said.

“You have instances like that where people are making lemonade out of lemons,” he added.

For Molnar, of Lee’s Enterprise, the opposite is true, as everything is taking longer to get done. Customers are ordering more parts ahead of time because of the long lead time needed to process the parts, he said. So in addition to ordering more parts to keep their prices lower, they are ordering parts even sooner, Molnar added.

Lower optimism

Sikich, a Naperville, Illinois-based consultancy and technology firm, released last week its latest Sikich Industry Pulse, a report on the manufacturing and distribution industry. The survey results were compiled from responses from 100 manufacturing and distribution executives questioned in June.

The survey showed that only 58% of manufacturing and distribution executives rated their optimism at a seven or higher on a scale of one to 10. This comes a year after 81% of rated their optimism at a seven or higher.

Two of the top three reasons for lower optimism are familiar to Molnar, Fisher and Goodreau – 16% of the executives named supply chain issues, while 10% said it was labor acquisition.

Supply chain and labor shortage issues also figured in how manufacturers are falling behind in meeting the demand of their customers. Forty-three percent of the executives surveyed said that supply chain obstacles causing a material shortage was the number one reason why their companies could not meet demand. Thirty-nine percent named the labor shortage as the cause for not being able to meet customer demand.

But Fisher, of S&H Machine, was not pessimistic about the future of his business.

“I need to find people and I need to find ways of automating,” Fisher said. “The fact that I have work is a good thing. Yeah, raw materials shortages are a problem, and lack of people is a problem. But if you have work, you have hope.”

Fisher said he felt good about the future and was confident that he would make it through this tough period.

“I have less competition than I did before, so that is a good thing,” he added. “There are some nice things that are there.”